Top American-Based Steel Casting Company Since 1979

If you’re looking for a reliable steel casting company with a strong record of quality, consistency, and service, Eagle Alloy is a trusted name. Since 1979, we’ve specialized in custom carbon and stainless steel castings, utilizing industry-leading shell molding and air-set casting processes. From concept to delivery, we offer expert guidance, advanced simulation tools, and end-to-end production to ensure every part meets your specifications.

Find Your Perfect Match

We cast a range of steel alloys, including carbon steel, stainless steel, and specialty grades, and support both prototype and high-volume production runs. We leverage our in-house capabilities to tailor each casting to the application’s tolerance, surface finish, and structural requirements.

From initial engineering and simulation through casting, heat treating, and final inspection, we provide full-service solutions tailored to your needs. Explore our complete list of casting services and capabilities.

Shell Molding

A high-precision process ideal for medium to large quantities. Shell molding offers fine surface finishes and tight dimensional tolerances (±0.030″ per inch). It’s especially effective for the repeatable production of complex steel parts.

Airset Casting

Also known as no-bake casting, this method uses chemically bonded sand that cures at room temperature. With tolerances of ±0.063″ per inch, it’s an excellent choice for prototypes, low-volume orders, or parts that require flexibility in geometry.

Rapid Prototyping

Our rapid prototyping services use 3D-printed sand molds to eliminate tooling costs and development time. Ideal for short runs under 100 pieces, this process supports fast iterations, complex geometries, and tight timelines.

Quality and Inspection

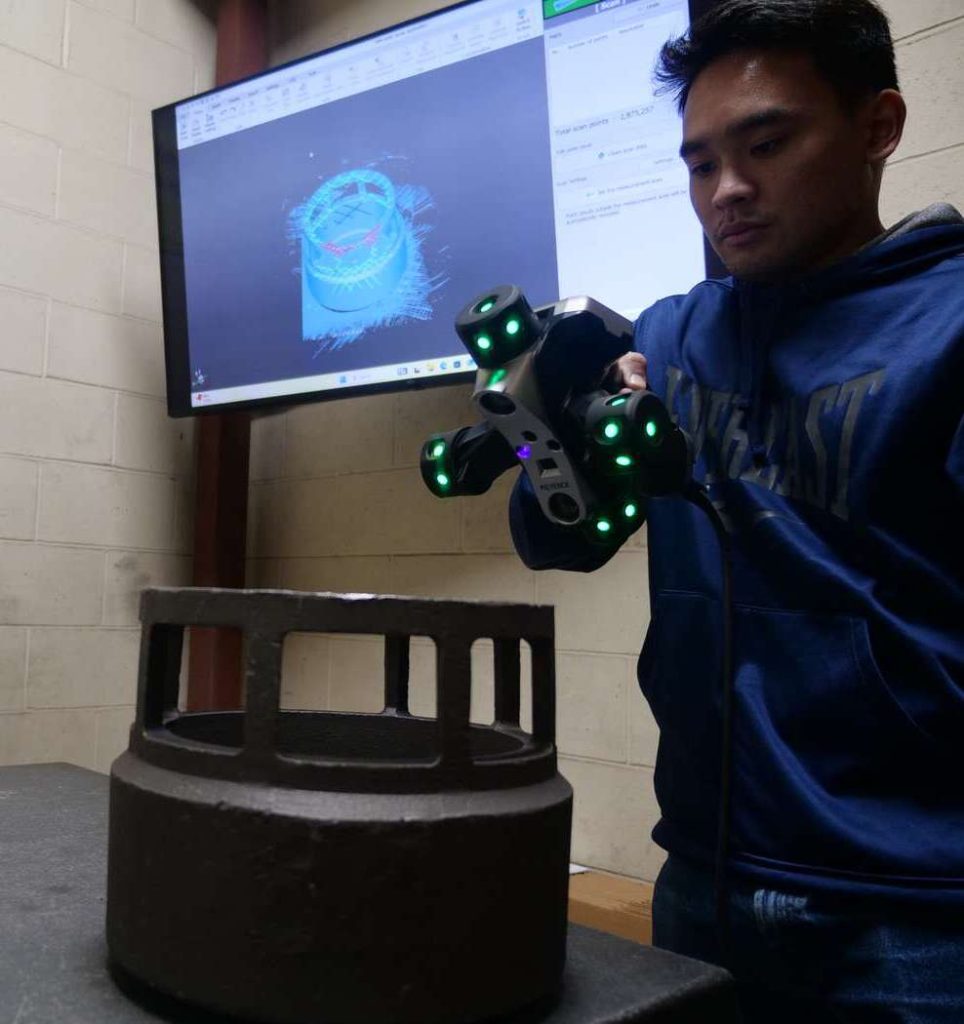

Eagle Alloy maintains a rigorous inspection process backed by in-house X-ray, spectrometry, laser scanning, mag particle, and hardness testing. We provide full material traceability and dimensional verification to ensure every part meets exact specs.

Dimensional Tolerance

Our standard tolerance ranges are based on the ASTM International Steel Castings Handbook and decades of production expertise. We maintain tight as-cast tolerances and advise on machine stock for full cleanup. Shell mold castings achieve ±0.030″ per inch; airset castings ±0.063″ per inch.

What Sets Eagle Alloy Steel Casting Company Apart?

Customer-First Production Model

Our sales team also functions as our production control team, streamlining communication and reducing delays. This structure has helped us maintain long-term relationships. Our very first customer has been with us for more than four decades.

Advanced Technology & Tooling

- Eleven coreless induction furnaces up to 5,000 lbs

- In-house 3D simulation (MAGMASOFT) and CAD design tools

- Keyence 3D laser scanning for precise inspection

- Full in-house X-ray and hardness testing capabilities

Design and Engineering Support

Our team applies Design for Manufacturability (DFM) and Value Engineering (VE) principles from the start of each project. This approach helps eliminate excess machining, improve part quality, and optimize casting flow before we pour a single mold.

Stay Up-to-Date With Eagle Alloy

Curious about metalcasting? Eagle Alloy and the Eagle Group have you covered. Explore our resource collection packed with insights into our manufacturing processes, industry updates, and company news.