Eagle Alloy’s steel casting facilities span 290,000 square feet in Muskegon, Michigan, and are built to support everything from intricate one-off prototypes to full-scale production runs. As the largest company within the Eagle Group, Eagle Alloy combines decades of experience with advanced equipment to deliver high-quality castings on time and to spec.

Whether you’re seeking shell mold or airset castings, our facility is fully equipped for precision metalcasting. From design simulation through heat treating and inspection, we manage every step of the process in-house for maximum quality control and turnaround efficiency.

Designed for Complex Steel Casting Projects

Our facilities feature dedicated production lines, integrated digital modeling, and real-time quality assurance capabilities. We support high-mix, high-precision work across a range of industries, including energy, defense, transportation, and agriculture.

Key capabilities include:

- Shell mold and airset mold production lines

- In-house sand coating and reclamation

- Multi-furnace melting with dual-trak induction

- Automated and manual grinding for gate removal

- Complete heat treating and x-ray inspection

- Real-time CMM and non-destructive testing

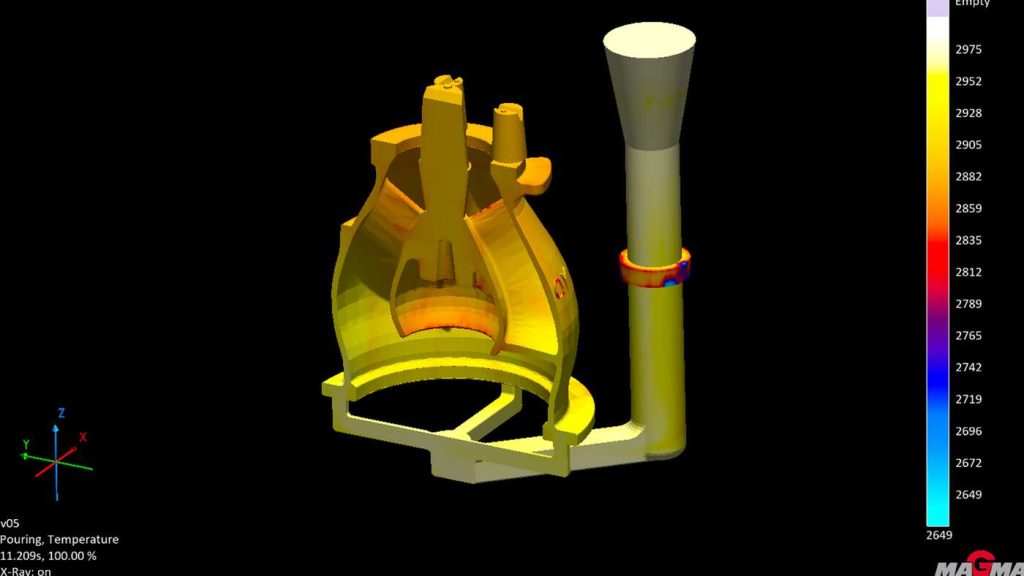

- Full CAD and casting simulation

- In-house heat treatment department

Explore our video and browse photos of Eagle Alloy’s steel casting operations in action—from shell core production to final inspection. It’s the first step in understanding what we can deliver.

Eagle Alloy Steel Casting Facility Equipment List

You can also download our most recent Eagle Alloy Facilities List for detailed specifications.

Melting & Pouring Equipment

- Six 5,300 lb. Dual-Trak Inductotherm Coreless Induction Furnaces with two 1750+KW Power Supplies

- Three 5,300 lb. Dual-Trak Inductotherm Coreless Induction Furnaces with 1750KW Power Supply

- Two 5,000 lb. and one 1,000 lb. Inductotherm Coreless Induction Furnaces with 1500KW Power Supply

- Fourteen Royer Pouring Tunnels

CAD Software

- Four seats of Solid Edge 3D Solid Modeling package

- One seat of Cimatron Software

- One seat of Fusion 360

Casting Simulation

- One seat of MAGMAsoft Solidification Simulation software (8-core license)

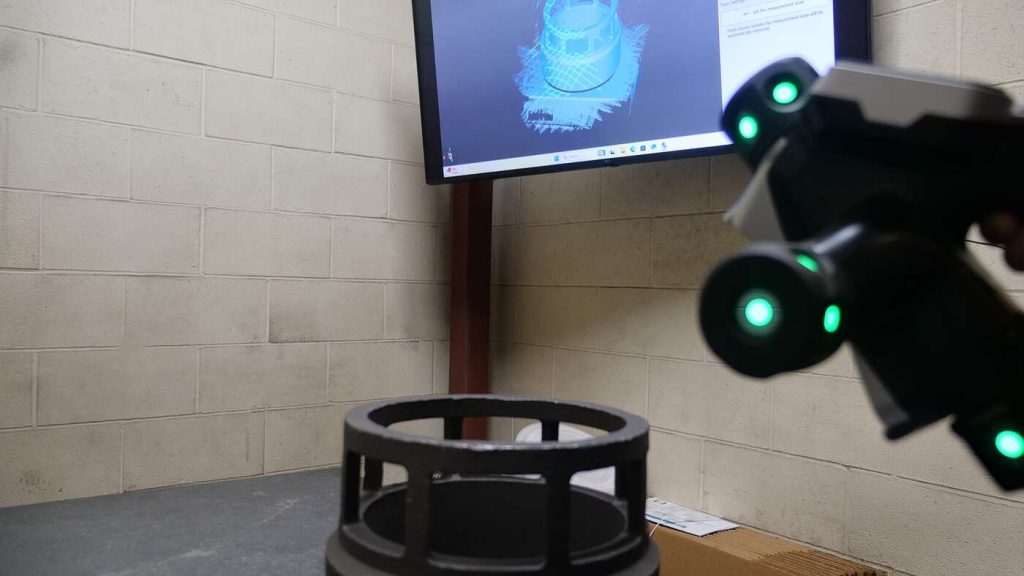

3D Laser Scanner

Sand Testing Equipment

- Two Hot Tensile testing machines

- Two Dietert Detroit Sand Hardness Testers

- Two Melt Point Test

- Sieve Pan Screen Tests

- Loss on Ignition (LOI) Test

- Shell Transverse Test

- One Dietert Ultrasonic Clay Scrubber

- One AmScope Microscope

- One Magnetic Agitator

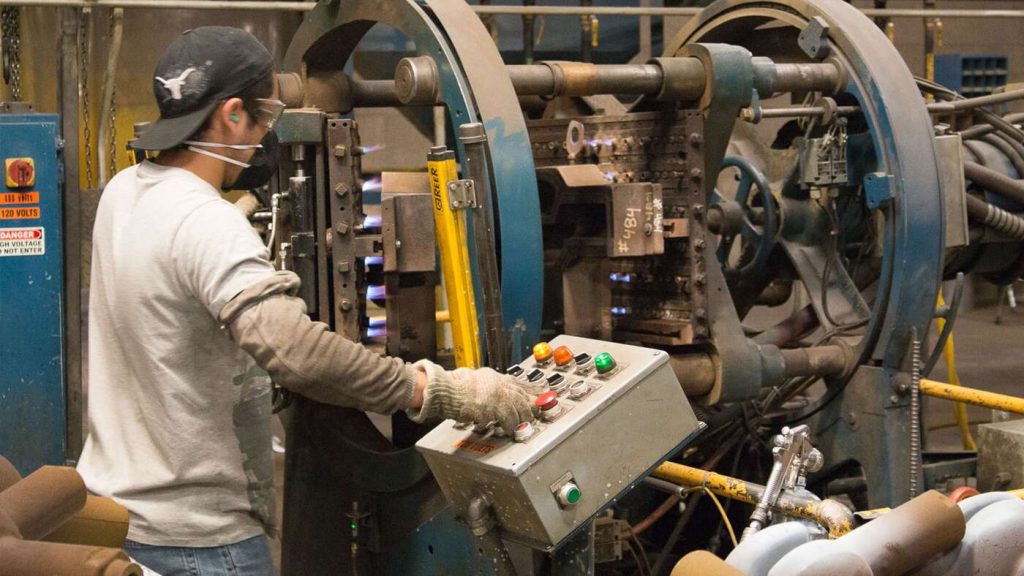

Shell Core & Mold Equipment

- One Shalco 15 X 20 Shell Molding Machine

- Nine Shalco 20 X 30 Shell Molding Machines capable of 30 x 40 molding

- Eleven Shalco 16 X 24 Shell Molding Machines

- Fifteen Redford Shell Core Machines

- Eight Shalco U180 Shell Core Machines

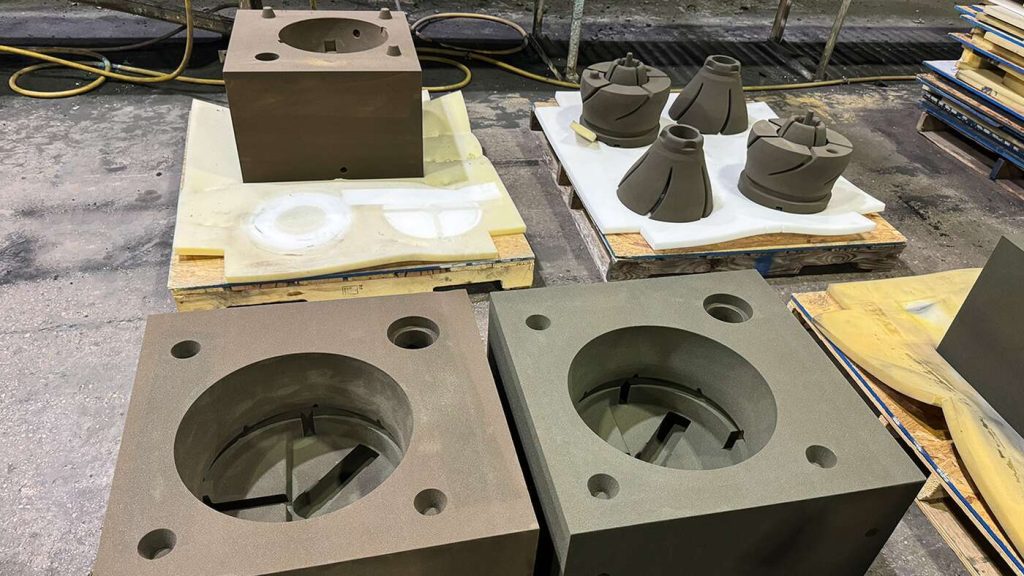

Airset Core & Mold Equipment

- One Palmer Mixer High Speed Auger Mixer for Airset Molding (300lbs/min)

- One Kloster Rollover

Cleaning & Gate Removal

- Twenty Lean Manufacturing Cells with synchronized torch, arc, and grind operations

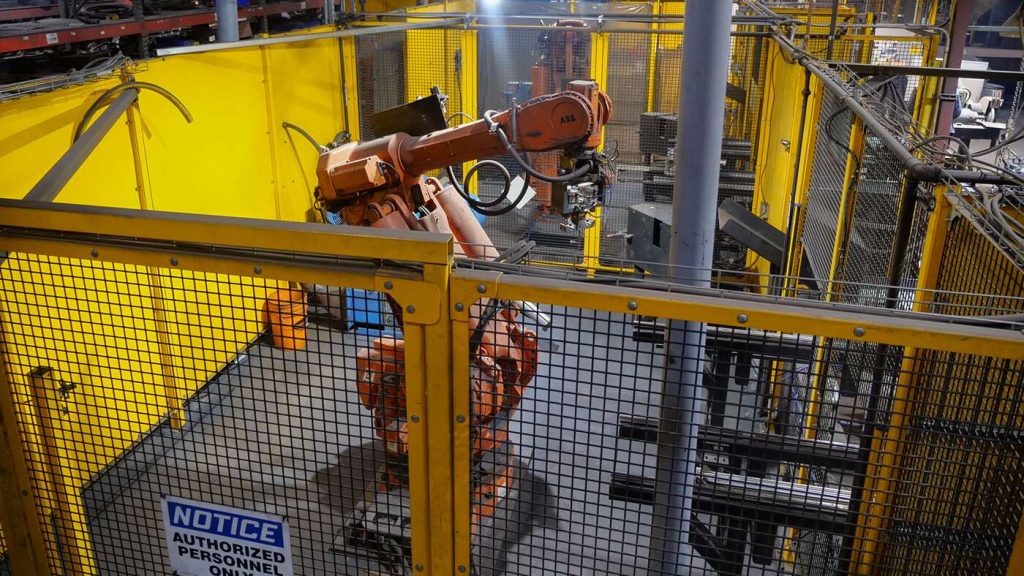

- Four ABB Robot Cells Equipped for Grinding Castings

- One Pangborn 4-in-1 Reclaimer; 34 Cubic Foot Blast & Reclaimer

- Three 34 Cubic Foot Pangborn Tumble Blasts

- One Empire Stainless Steel Grit and Bead blasting booth

- Seven Fox 30hp Snag Grinders with 30″ Wheels

- Thirty-Two 1000 Amp Miller Air Arcs

- Two Arc & Wire Feed Welders

- Assorted Handheld Air Tools

- Eight Dake Presses (two 150-Ton, six 100-Ton)

- Two Hypertherm Hand Plasma Arc Cutters

- Two AW Bell Belt Grinders #RGS460

- One GK Media Rotary Drum

- Six TIG Weld Stations

Sand Coating Plant Equipment

(Capable of Coating 9.5 Tons of Sand/Hour)

- One 200 Ton Sand Tower

- One 100 Ton Sand Tower

- Four 40 Ton Coated Sand Towers

- Sand Heater

- Continuous Mixer

- Batch Mixer

- Thermal Oxidizer

Quality Control & Testing Equipment

- Two Thermo Scientific ARL3460 spectrometers capable of running, but not limited to, carbon steel, stainless and nickel-base materials

- Two 5,000 AMP Magna-Flux Magnetic Particle Testers, Type H-710

- Dye Penetrant Capabilities

- Two Detroit Testing Machine Company Hydraulic Brinell Hardness Tester Model PHL-3

- Three 20x Bausch & Lomb BHN Scopes

- One Brinell Optical Scanning System, OS-300WC

- One Pantak HF320 X-Ray System

Material Handling Equipment

- Fourteen Toyota Electric Fork Trucks

Heat Treating

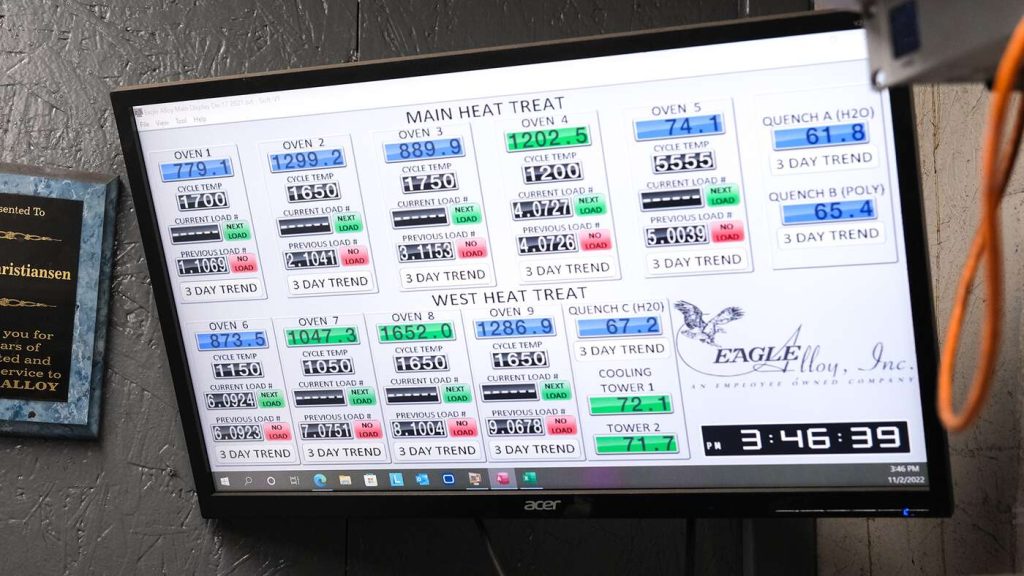

- Three Annealing & Normalizing Furnaces, capable of 2050° Maximum Temperature

- Two Water Quench Tanks

- One Quench & Temper Furnace with Polymer Quench System (2-rack capability)

- Six HTF Air Ratio Low Oxygen Heat Treat Furnaces

- One Thermal Care Water Cooling System

Air Power

- 300hp Gardner-Denver Compressor

- 350hp ATLAS COPCO Variable Speed Compressor

- 150hp Ingersoll Rand Compressor

- Two 125hp ATLAS COPCO

- One 150hp ATLAS COPCO

- ManagAIR System

Sand Reclamation Equipment

(Capable of reclaiming 4.25 Tons of Sand/Hour)

- One 200 Ton Trane Chiller

- One Calcafire Thermal Reclaimer

- One Deduster

- One 200 Ton Sand Tower

- One Simpson Proclaim Clay Scrubbe

Why It Matters

Having this level of in-house control means fewer delays, tighter tolerances, and more responsive service. Our steel casting facilities are built not just for scale, but for agility—helping you bring complex projects to market faster, without sacrificing quality.

Let’s Talk About Your Project

Whether you’re transitioning from a fabricated part to casting or starting a new design from scratch, Eagle Alloy has the tools and talent to deliver.