Reliable Quality Assurance in Steel Casting

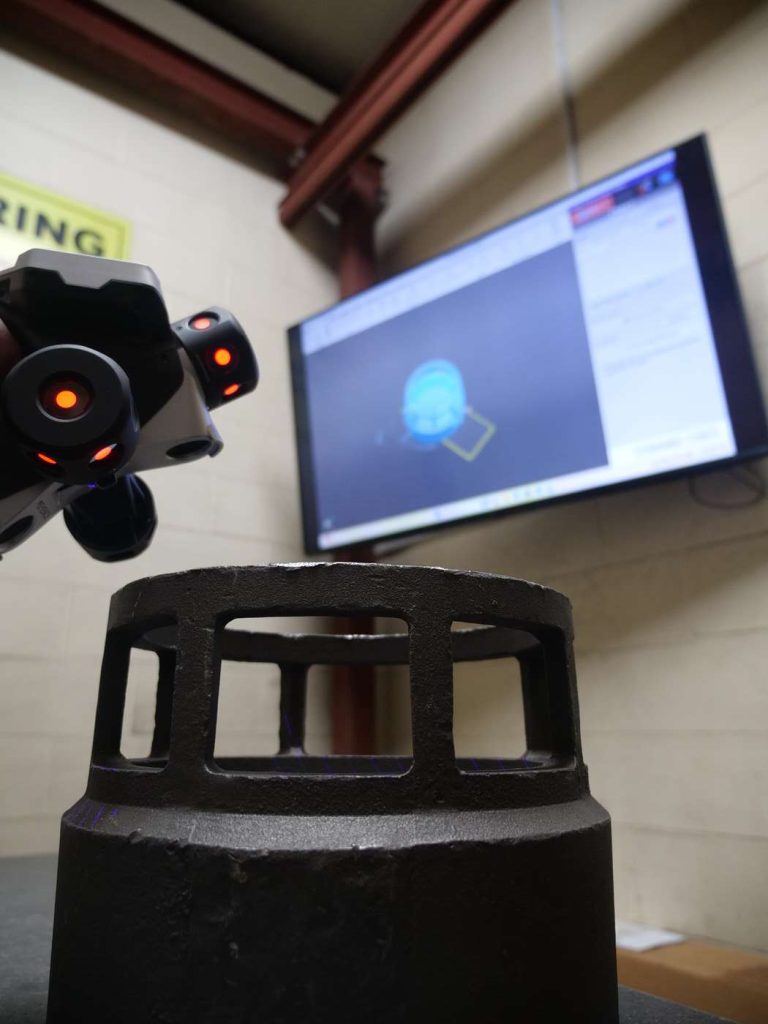

At Eagle Alloy, casting quality control is built into every project. As a member of the Eagle Group, we apply detailed inspections, proven processes, and modern tools to help customers get the results they need. From early simulation through final dimensional checks, we follow a clear process to support accuracy, consistency, and part performance.

Thorough Quality Checks from Day One

Before casting begins, our engineering team runs solidification simulations to review part geometry, optimize gating, and identify potential problem areas. This early quality work reduces rework and helps align results with the original CAD model.

Each casting is reviewed for size, shape, and tolerances before we move into full production. These proactive quality checks save time by avoiding costly flaws and improve product consistency across every order.

Eagle Alloy’s Inspection Tools and Capabilities

We maintain a complete set of inspection tools in-house to support casting quality control and help verify that each part meets required specifications:

- 3D scanning for fast part comparison

- Coordinate measuring machines (CMMs) for tight tolerances

- In-house X-ray systems for internal structure review

- Magnetic particle testing for surface flaws

- Spectrometer analysis for alloy verification

- Hardness testing (Brinell and Rockwell)

All inspection tasks are handled by trained staff using certified procedures and are guided by our dimensional tolerance standards.

Certifications and Compliance

Eagle Alloy maintains multiple certifications to meet domestic and international quality standards. These include:

ISO and PED Certifications

Eagle Alloy’s ISO and PED certifications meet the following standards:

- ISO 9001:2015 – ANSI/ISO/ASQ Q9001-2015

- Pressure Equipment Directive (PED) Annex I, Paragraph 4.3 of 2014/68/EU or 97/23/EC 7/2

RoHS and REACH Compliance

Eagle Alloy, Inc. also complies fully with the RoHS directive, RoHS2 (Directive 2002/95/EC RoHS Directive and with Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011) and the REACH regulation (Regulation (EC) No 1907/2006 – Registration, Evaluation, Authorisation and Restriction of Chemicals)

TSCA Compliance

Eagle Alloy, Inc. confirms that, to the best of our control and knowledge, all castings produced do not contain substances listed under the Toxic Substances Control Act, including PFAS.

Prop 65 Compliance

In compliance with California Proposition 65, the Safe Drinking Water and Toxic Enforcement Act of 1986, Eagle Alloy Inc. discloses listed chemicals that may be found in our steel castings, which are known to the state of California to carry a risk of cancer, birth defects, or other reproductive harm.

ITAR and SAM Registration

In addition to our certifications, Eagle Alloy is also registered with the ITAR (International Traffic in Arms Regulations) and the SAM (System for Award Management). By registering with these entities, we are able to streamline any manufacturing projects related to U.S. Government contracts, including those originating with the Department of Defense.

Get a Quote for Your Next Project

If you need a casting partner with solid inspection processes and a clear path from design to part approval, we’re ready to help. Our team creates parts that meet your needs and supports them with data you can trust.

Request a quote or contact our team.